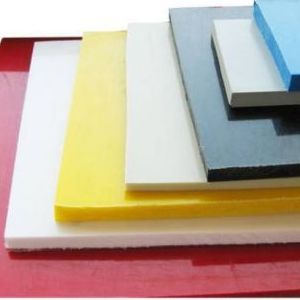

Polypropylene sheets

The polypropylene is produced in the form of white powder or granules with a bulk density of 0.4-0.5 g/cm³. Polypropylene produced a stabilized, colored and uncolored.

Preparation polypropylene

Polypropylene is prepared by polymerizing propylene in the presence of metal catalysts, such as Ziegler-Natta catalyst (e.g., a mixture of TiCl4 and AlR3): nCH2 = CH (CH3) → [-CH2-CH (CH3 ) -] n parameters needed for polypropylene are close to those at which the low density polyethylene was prepared. Thus, depending on the specific catalyst can be produced any type of polymer or mixtures thereof

The molecular structure polypropylene

According to the type of the molecular structure can be divided into three basic types:. Isotactic, syndiotactic and atactic . Isotactic and syndiotactic polypropylenes are the so-called stereoregular polymers. Isotactic polypropylene - a polymer in which methyl groups are directed to one side of the imaginary plane of the main chain; syndiotactic - methyl groups are strictly alternate; atactic -. methyl groups arranged randomly

Physical and mechanical properties of polypropylene

Unlike polyethylene, polypropylene, a less dense (density 0.90 g/cm3, which is the smallest value for all all plastics), a hard (abrasion resistant), a heat-resistant (starts to soften at 140 ° C, melting point 175 ° C), undergoes almost no corrosion cracking. It has high sensitivity to light and oxygen (sensitivity decreases when administered stabilizers).

Tensile Behavior polypropylene More greater extent than polyethylene, depends on the load application rate and the temperature. The slower the polypropylene of stretching, the greater the value of the indicators of the mechanical properties. At high stretching speeds the tensile breaking stress polypropylene considerably below its yield point in tension. Indicators of basic physico-mechanical properties of the polypropylene are given in Table:

|

Physical and mechanical properties of polypropylene |

|

| density, g/cm 3 | 0,90-0,91 |

| Breaking tensile stress, kgf/cm 2 | |

| elongation at break,% | 200-800 |

| The flexural modulus, kgf/6700-11900 | |

| tensile yield strength, kgf/cm 2 | 250-350 |

| elongation at yield,% | 10-20 |

| Impact strength notched, kgf · cm/cm 2 | 33-80 |

| Hardness Breen ellyu kgf/mm 2 | 6,0-6,5 |

Physico-mechanical properties of the polypropylene of different grades are given in table:

Physical and mechanical properties of polypropylene different brands

|

Performance/model |

01P10/002 |

02P10/003, |

03P10/005, |

04P10/010 |

05P10/020 |

06P10/040 |

07P10/080 |

08P10/080 |

09P10/200 |

| Bulk density, kg/l, at least | 0,47 | 0,47 | 0,47 | 0,47 | 0,47 | 0,47 | 0,47 | 0,47 | 0,47 |

| ≤0 | 0,2- 0,4 | 0,4-0,7 | 0,7-1, 2 | 1,2-3,5 | 3-6 | 5-15 | 15-25 | ||

| Elongation at break,%, at least | 600 | 500 | 400 | 300 | - | - | - | - | |

| yield strength at break kg/cm 2 , at least | 260 | 280 | 270 | 260 | 260 | - | - | - | - |

| Resistance to cracking, h, not less | 400 | 400 | 400 | 400 | - | - | - | - | |

| characteristic viscosity in decalin at 135ºC, 100 ml/g | - | - | - | - | - | 2,0-2,4 | 1,5-2,0 | 1,5-2,0 | 0,5-15 |

| The content of the isotactic fraction of at least | - | - | - | - | - | 95 | 93 | 95 | 93 |

| The content of atactic fraction, no more | - | - | - | - | - | 1,0 | 1,0 | 1,0 | |

| Frost, ºC, not higher than | - 5 | - 5 | - 5 | - | - | - | - | - | - |

The chemical properties of polypropene ilena

Polypropylene chemically resistant material. Noticeable impact on him have only a strong oxidizing agents - chlorosulfonic acid, fuming nitric acid, halogens, oleum. Concentrated 58% sulfuric acid and a 30% hydrogen peroxide at room temperature are negligible. Prolonged contact with these reagents at 60ºC or higher results in polypropylene degradation.

in organic solvents at room temperature polypropylene swells slightly. Above 100ºC it is soluble in aromatic hydrocarbons such as benzene, toluene. Data on the stability of polypropylene to the action of certain chemical reagents are shown in Table.

Sodium hydroxide, 40%70Slight

|

Chemical resistance polypropylene |

|||

|

Wednesday |

temperature, ° C |

Change of mass,% |

Note: |

| sample exposure duration in the medium reagent 7 days | |||

| Nitric acid, 50% | 70 | - 0,1 | Sample cracks |

| 90 | |||

| Hydrochloric acid, conc | 70 | ||

| 90 | + 0,5 | ||

| Length extracts the sample in the reagent medium 30 days | |||

| Nitric acid, 94% -s | 20 | - 0,2 | Sample fragile |

| Acetone | 20 | + 2,0 | |

| Gasoline | 20 | + 13,2 | |

| benzene | 20 | + 12,5 | |

| Caustic soda, 40% | 20 | Slight | |

| Mineral oil | 20 | + 0,3 | |

| Olive oil | 20 | + 0,1 | |

| Sulfuric acid, an 80% | 20 | Slight | weak staining |

| Sulfuric acid, 98% -s | 20 | & gt ; & gt; | |

| Hydrochloric acid, conc | + 0,2 | ||

| Transformer oil | 20 | + 0,2 | |

Due to the tertiary carbon atoms of polypropylene is more sensitive to oxygen, particularly when povy shennyh temperatures. This explains the much greater tendency to aging of polypropylene as compared with polyethylene. Aging polypropylene occurs at higher rates and is accompanied by a drastic deterioration of its mechanical properties. Therefore, polypropylene is used only in a stabilized form. Stabilizers prevent polypropylene from degradation both during processing and while in operation.

Polypropylene less prone to cracking than polyethylene under the influence of aggressive environments. He successfully withstand standard test for stress cracking, conducted in a variety of environments. Resistance to cracking in a 20% aqueous solution of the emulsifier OP-7 at 50ºC for polypropylene with a melt flow index of 0.5-2.0 g/10 min present in the tensioned state, more than 2000 h.

polypropylene - a water resistant material. Even after prolonged contact with water during 6 months (at room temperature), the water absorption of the polypropylene is less than 0.5%, and at 60 ° C - less than 2%

Thermal properties of polypropylene

Polypropylene. It has a higher melting temperature than polyethylene and accordingly a higher decomposition temperature. Pure isotactic polypropylene melts at 176ºC. The maximum operating temperature 120-140ºS polypropylene. All products of polypropylene withstand boiling and can be subjected to steam sterilization without any change of its shape or mechanical properties. Exceeding the heat resistance of polyethylene, polypropylene is inferior in hardiness. Its brittle temperature (frost resistance) ranges from -5 to -15 ° C. Frost resistance can be improved by introducing a macromolecule ethylene isotactic polypropylene (e.g., propylene in the copolymerization with ethylene). Indicators basic thermophysical properties of polypropylene are given in Table:

|

Thermal properties of polypropylene |

|

| melting temperature, ºC | 160-170 |

| The thermal resistance of NIIPP method, ºC | 160 |

| Specific heat (20 to 60C), cal/(g · ºC) | 0,46 |

| thermal linear expansion coefficient (20 to 100ºC), 1/ºC | 1,1 · 10 -4 |

| brittleness temperature, ºC | -5 to -15 |

The electrical properties of polypropylene

indicators electrical properties of polypropylene are given in table:

| Specific volume electrical resistivity, ohm-cm | 10 16 -10 17 |

| permittivity at 10 6 Hz | 2,2 |

| dielectric loss at 10 6 Hz | 2 x 10 -4 -5 x 10 -5 |

| Electric strength (sample 1 mm thick), kV/mm | 28-40 |

polypropylene Processing

extrusion molding methods, vacuum and blow molding, extrusion blow molding, injection blow molding, injection, compression molding, injection moldi g.

Application polypropylene

Material for the production of films (especially packaging), containers, tubes, parts technical unit urs, household items, non-woven fabrics, etc .; insulating material in construction for vibration noise insulation of ceiling in the "floating floor" systems, swimming pools, tanks for liquid, galvanic baths, fonts for baths, etc.